Diamond Technical Services, Inc is a full-service NDE company offering a comprehensive range of examination methods. The experience of our highly skilled technicians combined with our latest technology provides a safe, high quality and efficient product for every customer. We pride ourselves on response to the needs of our clients and the ability to react to changes. Our suite of services includes:

Radiographic | Ultrasonics | Magnetic Particle | Liquid Penetrant | Visual | Additional Services

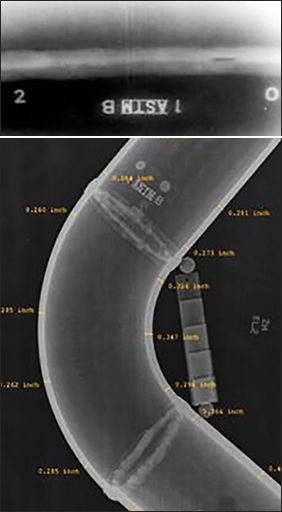

Radiographic examination employs a source of radiation, such as an X-ray tube or a radioactive isotope, to penetrate the material and produce a volumetric image.

Radiographic examination employs a source of radiation, such as an X-ray tube or a radioactive isotope, to penetrate the material and produce a volumetric image. Ultrasonic examination employs high-frequency sound waves to penetrate components allowing the analyzation of reflected sound for determination of internal quality, overall thickness, and other material properties.

Ultrasonic examination employs high-frequency sound waves to penetrate components allowing the analyzation of reflected sound for determination of internal quality, overall thickness, and other material properties. Magnetic Particle examination detects discontinuities in ferrous metal at or near the surface after a magnetic field has been induced in the component and the application of a ferrite powder or liquid solution. The applied media is attracted to the magnetic flux leakage of the discontinuity. This method allows visual interpretation of the discontinuity.

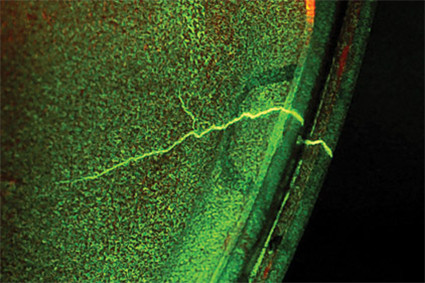

Magnetic Particle examination detects discontinuities in ferrous metal at or near the surface after a magnetic field has been induced in the component and the application of a ferrite powder or liquid solution. The applied media is attracted to the magnetic flux leakage of the discontinuity. This method allows visual interpretation of the discontinuity. The Liquid Penetrant method employs capillary action to expose surface flaws in any solid material. Visible or fluorescent dye on a contrasting background allows for enhanced visual inspection.

The Liquid Penetrant method employs capillary action to expose surface flaws in any solid material. Visible or fluorescent dye on a contrasting background allows for enhanced visual inspection. Most codes and standards require visual VT exams as the first NDE method to assure proper adherence to product design and quality. This step, if followed properly by individuals trained and certified to thoroughly inspect and disposition the components, can save a project the time and cost of performing further NDE prematurely.

Most codes and standards require visual VT exams as the first NDE method to assure proper adherence to product design and quality. This step, if followed properly by individuals trained and certified to thoroughly inspect and disposition the components, can save a project the time and cost of performing further NDE prematurely. Additional Testing Methods

Additional Testing Methods